- +91 - 95 60 222 333

Sometimes the highly pitted flow-meters fall out of fluid flow calibration. Over time, the performance of all the instruments depreciates with different types of wear and tear. The flow of the media through the flow-meters can be affected by corrosion and dirt. Temperature variations may also damage during the process.

With the potent measurement of fluid flow and the process by the conditions of use, all the measurement devices are influenced. The situations under which the meter will be in practice may have an impossible standard.

To define a set of operations, together with influence factors, the standard, the device and combinations of fluids are used to provide the calibration. The meaningful prospect of how the device will function when in use, is expressed in such a way.

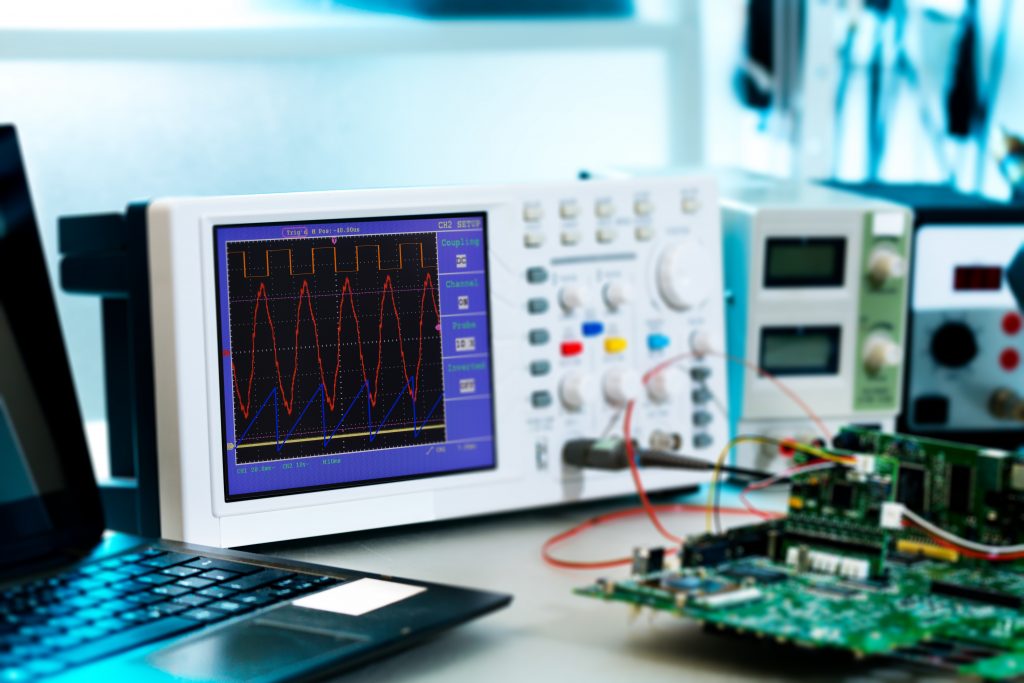

Sigma is fully equipped with instruments like Reference Flow Monitor and Laminar Flow Monitor, for the calibration of Rotameter and Mass Flow Meter.

Rotameters are widely used in process industries. Rotameters are used in systems that involve a liquid or gas travelling through a tube.

For example, rotameters are used in oil pipelines to measure the flow rate of oil as it is dispersed from one location to another across great distances. Portable rotameters can also be constructed to measure the flow rate of large bodies of liquid or gas, such as rivers, oceans, streams, as well as the atmosphere. These portable rotameters can simply be dunked into the substance they are measuring in order for a measurement to be taken.

Use in an Orifice Bypass

To cost-effectively handle larger flow rates of liquids or gases, a rotameter can be installed in a bypass line around an orifice plate. The differential pressure produced by the orifice causes a relatively low flow through the rotameter that can be a measure of flow through the main pipeline.

Key benefits include:

- Useful in situations, where the measurement must be made in a hazardous or remote area, or where electric power is either not available or would be potentially dangerous.

- Rangeability that can be 121/2:1, as compared to 4:1 for DP meters

- Scale readings that can be graduated into direct units for flow in the main pipeline

- Changing the range or cleaning the tube, without disassembling the meter or removing it from the bypass line.

Calibration of rotameter is essential

- The standard that you use to calibrate a flowmeter must be accurate enough to perform the calibration. The general thumb rule is that your standard should be four times more accurate than the unit under test (UUT); however, this can vary depending on the requirements of the fluid flow calibration.

- Your standard should be traceable to a recognized standard. Traceability provides an unbroken chain of documentation that shows, how the measurements it makes are comparable to even more accurate standards. Traceable measurements help you prove that your measurements are what your flowmeter shows, within specific ranges.

- The rate of flow between the UUT and the calibration standard must be in a steady-state. Since the flow rate of the standard and the UUT are compared in real-time during calibration, the system flow rate should not vary with time.

- All media measured by the calibration standard must also be measured by the flowmeter at the same time. In other words, there should not be any leaks or significant temperature changes, in intermediary volumes, that might affect the measurement.

- You should perform the calibration under conditions that are typical for the flowmeter’s actual operation. For example, the viscosity, density or heat content of the liquid being measured can affect the flowmeter readings based on its operating technology. It is important to match the calibration services with the flowmeter’s application.

Want to speak to our Customer Care Executive?

Just Submit Your Contact Details and We’ll be get in Touch With You Shortly.